The reconstruction of the Luzhniki Grand Sports Arena was carried out in order to prepare the country's main arena for hosting the 2018 FIFA World Cup final. The versatility of the arena allows it to host not only the most important sports competitions, but also high-tech mass cultural and entertainment events. The main task in creating the exterior and interior layout of the facility was to preserve the historical architectural appearance of the stadium and comply with FIFA requirements, including protecting spectators from natural precipitation in the form of rain or snow.

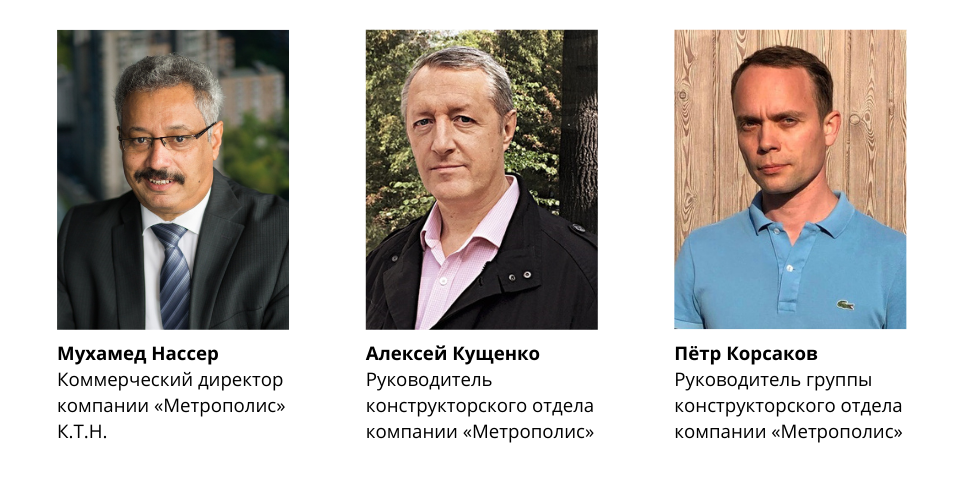

Mohamed Nasser, Commercial Director of Metropolis, Aleksey Kuschenko, Head of Structural Engineering department at Metropolis, Pyotr Korsakov, Head of group in Structural Engineering department at Metropolis, told Sport Build about how the design and reconstruction of the roof of the stadium took place.

In 1956 - 1957 in Moscow, the Luzhniki stadium was built with a main sports arena for 100,000 seats. The unique large-span roof of the stadium was built in 1997. The roof erected over the GSA is a unique structure measuring 247.8 × 308.6 m. The height of the roof from the head of the columns to the top of the structure is 25.6 m. The roof rests on steel columns 25.7 m long, with a section of 800 × 800 from a sheet of 16 mm. The roof structure consists of external and internal contours, radial beams, ring trusses and ties. The mass of steel roofing, taking into account the supporting columns and an additional canopy, was about 18,000 tons.

The main load-bearing structures and their elements are made of chrome-silicon-nickel alloy sheet steel with a design resistance of 380 MPa. Auxiliary roof structures are made of rolled profiles, steel C345. The roof covering is designed from sheets of cellular translucent polycarbonate on an aluminum subsystem. According to the 1995 project, a sliding roof was provided over the football field, which was supposed to move along guides located on the inner contour. Since the sliding roof option was not implemented, there was a margin for bearing capacity. This made it possible to implement the idea of reconstruction, namely, to build up the roof in the form of a canopy with an overhang of 11,700 mm and to hang two scoreboards on the inner contour.

Calculation and design

To calculate the roof of the Luzhniki Grand Sports Arena, the Lira-SAPR calculation complex was used. The calculations verified the bearing capacity, as well as local and general stability. Since the roof was an existing structure, several design schemes were created that corresponded to the roof in terms of geometry and boundary conditions. The main criterion for the correctness of the construction of the schemes was the comparison of the results of calculations with the results of field observations and the results of calculations of Research Institute of Building Constructions (TSNIISK) named after V. A. Koucherenko. The verification of the bearing capacity in the design schemes was carried out under the action of horizontal and vertical constant, long-term and short-term design loads in a spatial setting, taking into account joint work and boundary conditions (base compliance). The calculation scheme included more than 1 million elements. With the help of modern techniques, the calculation assumptions of the authors of the 1995 project were verified. The results obtained almost coincided both with the calculations of 1995 and with field observations. Calculations and modeling of the roof were carried out in close cooperation with TSNIISK named after V.A. Kucherenko, Candidate of Technical Sciences Mikhail Iosifovich Farfel provided support for modeling and analysis of calculation results. Mikhail Iosifovich is also one of the authors of the 1995 GSA roofing project. Thus, when designing a unique structure, a link between generations was realized. For the period of reconstruction of the reinforced concrete frame of the stadium, it was necessary to disconnect the vertical ties that unfasten the roof from the stadium structures, since the entire frame was dismantled, with the exception of the facade. To unfasten the roof structure for the period of construction work, cross vertical connections between the columns were provided along the roof perimeter. Appropriate calculations were carried out, which confirmed the stability of the roof for the installation period.

Reconstruction results

A canopy was built to protect the front rows of stands of the reconstructed stadium from precipitation. The roof covering panels were raised to fit seamlessly into the canopy covering, which also had a positive effect on the aesthetics of the property. The friso of the roof was updated - panels made of golden perforated metal with images of athletes were installed. The design of the friso was developed by Artemy Lebedev's studio. The drawings are made up of holes of different diameters, which creates the illusion of gradation of halftones. The dynamics of the illustrations is supported by the rhythm of the facade elements. The execution technique provides good ventilation and complies with fire safety standards. As part of the reconstruction, the protective and decorative coating of the main structures of the GSA roof was updated, the enlargement joints were revised, and the failed high-strength bolts were replaced. A media roof has been installed, which is perfectly visible from the observation deck of the Vorobyovy hills. Following the results of the reconstruction and the World Cup 2018, FIFA recognized the Luzhniki stadium as the best arena in the world in terms of field visibility from the stands.